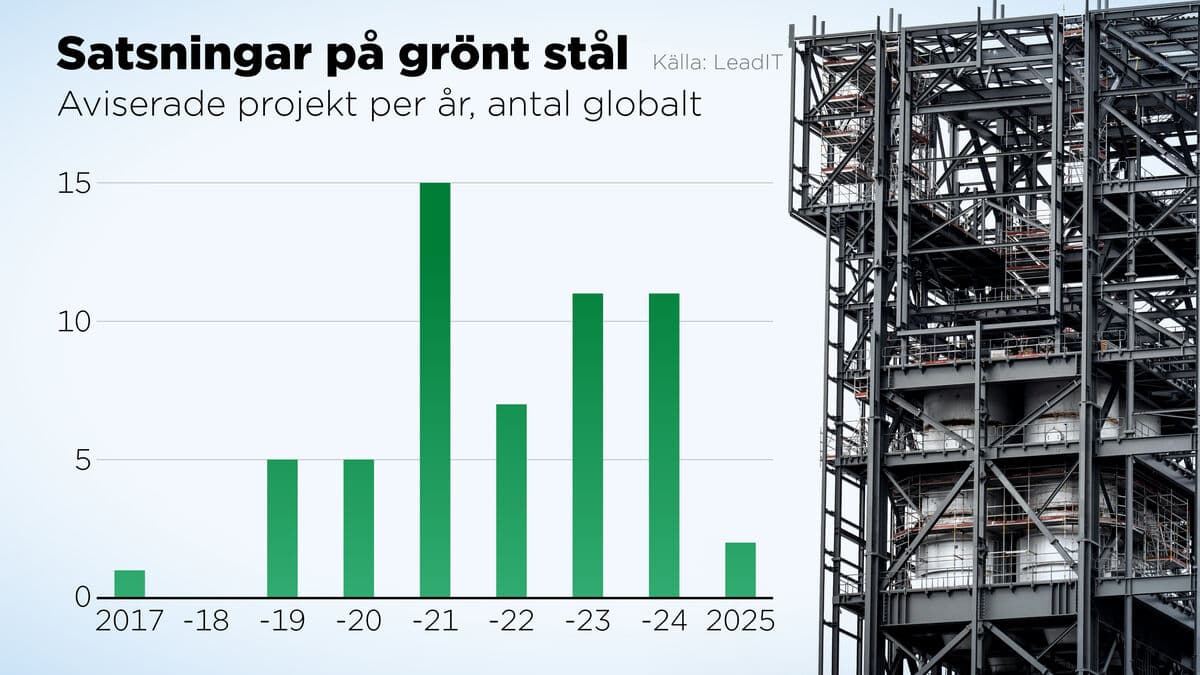

Last year was a dark year for green steel and iron production, which is the idea of manufacturing those products without the enormous greenhouse gas emissions associated with the industry.

"We are seeing a slowdown in momentum. There are significantly fewer announcements and there are some projects that have been put on hold or stopped, especially in Europe," says Aaron Maltais.

He is a group leader at SEI and works with the Green Steel Tracker for the high-level initiative Leadit (Leadership Group for Industry Transition), which tracks developments in the industry.

Luxembourg steelmaker ArcelorMittal announced last year that it was scrapping two major projects in Germany and postponing investments in Spain and France. Germany's Salzgitter and Sweden's SSAB were among the companies that delayed their green investments, in Salzgitter's case by three years.

The first one is important

High hydrogen prices combined with low steel prices make it difficult.

"It's not an easy equation to put together. You had very high ambitions a few years ago and when you try to implement them, it turns out to be more difficult than you thought."

There is no major producer of green steel or iron today. But the Swedish ventures Hybrit and Stegra are far ahead.

Stegra, where the facility in Boden is 60 percent complete, is at the forefront - and is important, he says.

"Getting the first large-scale production facility in place is very important to show that there is a market for green steel, that the deal can go through and that the technology can work on a large scale," says Maltais.

Big challenges

At the same time, the project is facing financial problems, and some analysts believe it could collapse. However, Maltais does not believe that this would mean the end of green steel.

The EU's emissions trading system means that companies cannot turn a blind eye to the requirements, according to Aaron Maltais.

"It may take a few years before we see an upturn again. But all large companies must deal with this issue. They must have a strategy and will not be able to turn a blind eye to the demands to change."

Gustav Sjöholm/TT

Facts: Green steel

TT

Green steel, or fossil-free steel as it can be called, means that production emits at least 85 percent less greenhouse gases compared with traditional steelmaking - under 300 kilograms of carbon dioxide per ton of steel.

In Sweden, the iron and steel industry accounted for 5 million tons of greenhouse gas emissions in 2024, more than a third of the industry's emissions.

Production can be done using hydrogen and electricity.

Green Steel Tracker does not take into account green recycling of scrap, nor does it take into account carbon capture and storage (CCS).

Sources: Green Steel Tracker (Leadit), Swedish Environmental Protection Agency